Luke Steel, based in Houston, Houstan, stands out as a leading manufacturer and supplier of high-quality Carbon Steel A350 LF2 Bars, delivering precision-engineered solutions to a variety of industries. Known for their commitment to quality, reliability, and customer satisfaction, Luke Steel offers A350 LF2 bars that adhere to strict standards for low-temperature applications. These bars are trusted by sectors like oil and gas, petrochemicals, power generation, and construction due to their impressive strength, toughness, and machinability. With a focus on efficient logistics and rigorous quality control, Luke Steel has become a reliable partner for carbon steel bar needs around the globe.

The Carbon Steel A350 LF2 Bar is primarily made up of carbon, manganese, phosphorus, sulfur, and silicon, with trace amounts of nickel and other elements added to boost impact toughness in low temperatures. These bars deliver a good yield strength of about 250 MPa and tensile strength ranging from 485 to 655 MPa. They are known for their excellent notch toughness, ductility, and weldability, making them dependable in cold service conditions. The well-balanced chemical composition helps prevent brittle fractures, making A350 LF2 bars ideal for critical pressure systems that require both durability and strength.

| Standard | ASTM A350, ASME SA350 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

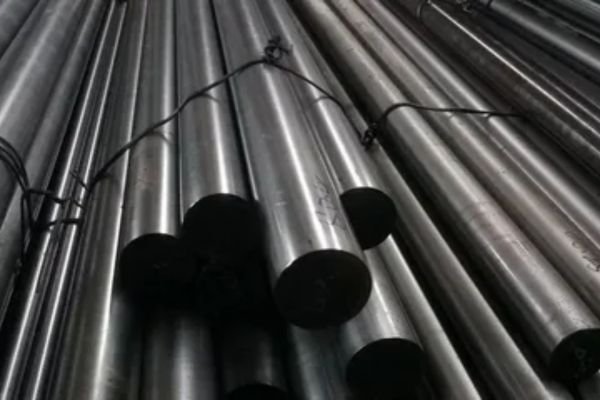

| Round bar Size | Diameter: 3-~800mm |

| Hex Bar Size | 2-100mm A/F |

| Square Bar Size | 4 to 100mm |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Hardened & tempered, annealed |

| Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Grade | C | Si | Mn | P | S | Cr | Mo | Cu | Nb | V |

| LF2 | ≤0.30% | 0.15 – 0.30% | 0.60 – 1.35% | ≤0.035% | ≤0.040% | ≤0.30 % | ≤0.12% | ≤0.40% | ≤0.02% | ≤0.08% |

| Grade | Tensile strength, (MPa) | Yield (0.2%) (MPa) | Elongation (%) | Reduction of Area (%) | Hardness HB |

| LF2 | 485-655(70-95KSi) | 250(36KSi) | 22 | 30 | ≤197HB |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Jaxon Steel is a trusted manufacturer and supplier of high-quality Carbon Steel A350 LF2 Bar in Houstan, USA. We specialize in premium steel products, including Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our extensive inventory also includes Pipes, Tubes, Flanges, Forged Fittings, Sheets, and Plates. Committed to fast delivery and exceptional customer service, we use only the finest raw materials to ensure superior strength, durability, and performance in critical industrial applications.

| STANDARD | UNS | WERKSTOFF NR. |

| ASTM A350 LF2 | K03011 | 1.0508 |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

| Diameter(Inch) | Carbon Steel LF2 Bar Size | Diameter (millimeter) | Carbon Steel LF2 Bar Size | Diameter (millimeter) | Carbon Steel LF2 Bar Size | Diameter (millimeter2) | Carbon Steel LF2 Bar Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Diameter in inch | Size in inch/MM | Weight Lbs/ft & Kg/M |

| 1/16 | 0.0625 1.5875 | 0.010 / 0.01488 |

| 1/8 | 0.125 3.175 | 0.042 / 0.062496 |

| 3/32 | 0.0938 2.38252 | 0.0240 / 0.035712 |

| 5/32 | 0.1563 3.97002 | 0.065 / 0.09672 |

| 7/32 | 0.2188 5.55752 | 0.128 / 0.190464 |

| 3/16 | 0.1875 4.7625 | 0.094 / 0.139872 |

| 1/4 | 0.25 6.35 | 0.167 / 0.248496 |

| 5/16 | 0.3125 7.9375 | 0.260 / 0.38688 |

| 9/32 | 0.2813 7.14502 | 0.211 / 0.313968 |

| 3/8 | 0.375 9.525 | 0.376 / 0.559488 |

| 1/2 | 0.5 12.7 | 0.668 / 0.993984 |

| 7/16 | 0.4375 11.1125 | 0.512 / 0.761856 |

| 9/16 | 0.5625 14.2875 | 0.844 / 1.255872 |

| 11/16 | 0.6875 17.4625 | 1.264 / 1.880832 |

| 5/8 | 0.625 15.875 | 1.043 / 1.551984 |

| 3/4 | 0.75 19.05 | 1.502 / 2.234976 |

| 7/8 | 0.875 22.225 | 2.045 / 3.04296 |

| 13/16 | 0.8125 20.6375 | 1.761 / 2.620368 |

| 15/16 | 0.9375 23.8125 | 2.35 / 3.4968 |

| 1 1/16 | 1.0625 26.9875 | 3.012 / 4.481856 |

| 1 | 1 25.4 | 2.671 / 3.974448 |

| 1 1/8 | 1.125 28.575 | 3.38 / 5.02944 |

| 1 1/4 | 1.25 31.75 | 4.173 / 6.209424 |

| 1 3/16 | 1.1875 30.1625 | 3.77 / 5.60976 |

| 1 5/16 | 1.3125 33.3375 | 4.598 / 6.841824 |

Carbon Steel A350 LF2 Bars find extensive use in applications that demand reliable performance in low-temperature settings, such as pressure vessels, flanges, fittings, valves, and pipeline components. They are commonly found in oil and gas facilities, offshore platforms, petrochemical plants, refineries, and power generation stations where resistance to brittle fracture is crucial. These bars are preferred for their machinability and ease of fabrication, ensuring cost-effective and sturdy assemblies in piping systems and structural frameworks that face low operating temperatures and challenging working conditions.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved