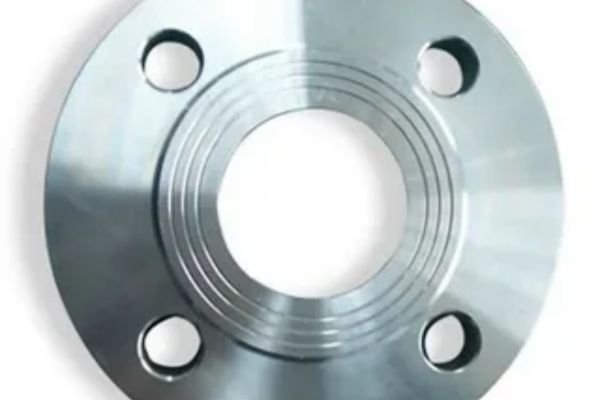

Luke Steel specializes in manufacturing and supplying Alloy Steel F22 Flanges in Houston, USA. These flanges provide high-performance solutions for high-pressure and high-temperature industrial applications. Alloy Steel F22 contains 2.25% chromium and 1% molybdenum, ensuring excellent resistance to heat, oxidation, and pressure. They are widely used in power generation, chemical processing, and petroleum industries, where flanged connections must withstand tough conditions. With their ability to perform reliably under thermal stress, F22 flanges are the top choice for engineers needing durability, strength, and safety in complex piping systems and high-temperature infrastructure.

Alloy Steel F22 Flanges consist of 2.25% chromium and 1% molybdenum, providing excellent resistance to oxidation, thermal fatigue, and high-pressure situations. These flanges have a tensile strength of 620 to 790 MPa, a yield strength of around 450 MPa, and an elongation of 20%. F22 retains structural integrity at temperatures up to 600°C, making it suitable for critical applications. The alloy is also resistant to hydrogen damage and scaling, ensuring long-term reliability in corrosive and high-stress systems. Its weldability enhances its usability in complex piping systems, ensuring secure, leak-proof connections.

Alloy Steel Flanges Specification : ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges : BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

| Grade | C | Mn | P | S | Si | Ni | Ch | Mo | Cb |

|---|---|---|---|---|---|---|---|---|---|

| F22 | 0.05-0.15 | 0.30-0.60 | 0.040 | 0.040 | 0.50 | – | 2.00-2.50 | 0.87-1.13 | – |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| F22 | 415 | 205 | 20 | – | 170 max |

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Alloy Steel F22 | K21590 | 1.7380 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| Nom. Pipe Size | O | T | R | X | No./Dia. of Holes | Bolt Circle Dia. | L2 | H | B2 | L | B | r | L3 | B3 | D |

| 1/2 | 3.5 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.9 | 0.38 |

| 3/4 | 3.88 | 0.5 | 1.69 | 1.5 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.5 |

| 1-1/4 | 4.62 | 0.62 | 2.5 | 2.31 | 4-0.62 | 3.5 | 2.25 | 1.66 | 1.38 | 0.81 | 1.7 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.9 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.5 | 2.38 | 2.07 | 1 | 2.44 | 0.31 | 1 | 2.46 | 0.69 |

| 2-1/2 | 7 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.5 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.5 | 0.94 | 5 | 4.25 | 4-0.75 | 6 | 2.75 | 3.5 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.6 | 0.81 |

| 3-1/2 | 8.5 | 0.94 | 5.5 | 4.81 | 8-0.75 | 7 | 2.81 | 4 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.1 | 0.88 |

| 4 | 9 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.5 | 3 | 4.5 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.6 | 0.94 |

| 5 | 10 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.5 | 3.5 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11 | 1 | 8.5 | 7.56 | 8-0.88 | 9.5 | 3.5 | 6.63 | 6.07 | 1.56 | 6.72 | 0.5 | 1.56 | 6.75 | 1.06 |

| 8 | 13.5 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4 | 8.63 | 7.98 | 1.75 | 8.72 | 0.5 | 1.75 | 8.75 | 1.25 |

| 10 | 16 | 1.19 | 12.75 | 12 | 12-1.00 | 14.25 | 4 | 10.75 | 10.02 | 1.94 | 10.88 | 0.5 | 1.94 | 10.92 | 1.31 |

| 12 | 19 | 1.25 | 15 | 14.38 | 12-1.00 | 17 | 4.5 | 12.75 | 12 | 2.19 | 12.88 | 0.5 | 2.19 | 12.92 | 1.56 |

| 14 | 21 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5 | 14 | 13.25 | 2.25 | 14.14 | 0.5 | 3.12 | 14.18 | 1.63 |

| 16 | 23.5 | 1.44 | 18.5 | 18 | 16-1.12 | 21.25 | 5 | 16 | 15.25 | 2.5 | 16.16 | 0.5 | 3.44 | 16.19 | 1.75 |

| 18 | 25 | 1.56 | 21 | 19.88 | 16-1.25 | 22.75 | 5.5 | 18 | 17.25 | 2.69 | 18.18 | 0.5 | 3.81 | 18.2 | 1.94 |

| 20 | 27.5 | 1.69 | 23 | 22 | 20-1.25 | 25 | 5.69 | 20 | 19.25 | 2.88 | 20.2 | 0.5 | 4.06 | 20.25 | 2.13 |

| 22 | 29.5 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22 | 21.25 | 3.13 | 22.22 | 0.5 | 4.25 | 22.25 | 2.38 |

| 24 | 32 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.5 | 6 | 24 | 23.25 | 3.25 | 24.25 | 0.5 | 4.38 | 24.25 | 2.5 |

Luke Steel is a top manufacturer and supplier of high-quality Alloy Steel F22 Flanges products in Houstan, USA. Specializing in steel solutions, we provide a wide range of products, including Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel. Our offerings include Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates. Known for our reliable delivery and superior customer service, we are committed to offering top-tier steel materials that ensure durability and performance across a wide range of industrial applications. We strive to meet the highest standards, making us a trusted partner for all your steel needs.

F22 Flanges are commonly used in steam lines, boiler components, heat exchangers, and turbine systems in power plants and petrochemical facilities. With excellent heat resistance and mechanical stability, they are ideal for high-pressure piping and critical reactor systems. F22 is also used in chemical reactors and pressure vessels where resistance to corrosion, thermal fatigue, and oxidation is crucial. Luke Steel provides F22 flanges in various sizes, ensuring precise dimensions and a secure seal for piping systems exposed to high thermal and mechanical stresses. These flanges deliver long-term performance, reducing maintenance needs and improving overall system reliability.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved