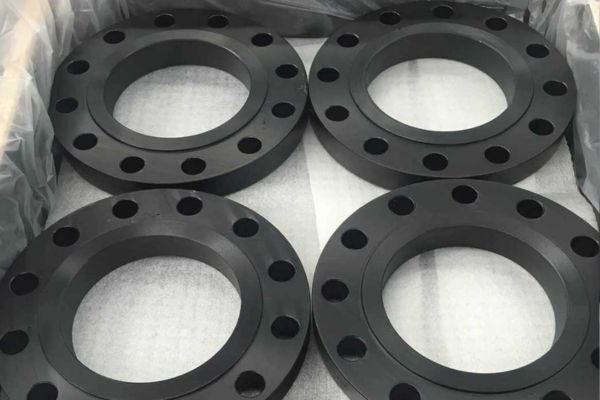

Luke Steel is one of the major manufacturers and suppliers of Carbon Steel A105 Flanges in Houstan, Houstan, renowned for providing high-quality industrial piping fittings. With its reputation as a reliable, precise, and timely service provider, Luke Steel provides a vast array of A105 flanges made to international standards and specifications. Our advanced facilities and seasoned staff guarantee us consistent performance and quality, which is why we are the choice among oil & gas, petrochemical, and construction industries. Luke Steel values customer satisfaction, competitive market prices, and technical superiority in every project we undertake.

Carbon Steel A105 Flanges consist mostly of carbon (up to 0.35%), manganese, phosphorus, sulfur, and silicon, making us best suited for high-pressure and high-temperature applications. These flanges have superior mechanical strength with tensile strength of 485 MPa and yield strength of 250 MPa. They have good ductility and hardness as well, providing long life under stress. A105 flanges are normalized for improved grain structure with enhanced toughness and resistance to wear by mechanical means. They have chemical and mechanical properties that qualify them to be used in seamless and forged pressure system parts operating in harsh environments.

| Specs | ASTM A105/ ASME SA105 |

|---|---|

| Pressure Classes | Cl 150, Class 300, Cl. 400, 600, Class 900, Cl 1500 and 2500 |

| Standards | ASME | BS | DIN | ANSI | GOST | EN Flange |

| Size Ranges | From 1/2 inch (i.e. 15 NB) upto 48 inch (i.e. 1200NB) |

| Flange Face Type | FF, RF, LMF, SMF, RTJ, LJF. |

| JIS Standards | 5 K, 10K, 16K, 20 K, 30K, 40K, 63 K |

| UNI/ DIN / EN Standard | 6Bar, 10 Bar, 16Bar, 25 Bar, 40Bar |

| Elements | Composition, % |

| Carbon [C] | ≤0.35 |

| Manganese [Mn] | 0.60-1.05 |

| Phosphorus [P] | ≤0.35 |

| Sulfur [S] | ≤0.40 |

| Silicon [Si] | 0.10-0.35 |

| Copper [Cu] | ≤0.40 |

| Nickel [Ni] | ≤0.40 |

| Chromium [Cr] | ≤0.30 |

| Molybdenum [Mo] | ≤0.12 |

| Vanadium [V] | ≤0.08 |

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Luke Steel is one of the most prominent manufacturers and suppliers of superior quality Carbon Steel A105 Flanges in Houstan, USA. As experts in steel solutions, we supply a complete spectrum of products like Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our product range comprises Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets, and Plates. Known for our reliable delivery and first-rate customer service, we are committed to supplying high-quality steel materials that guarantee durability and excellent performance in numerous industrial applications.

| ASTM A105 Flange Weights by Pressure Class and Size | ||||||||||||||||||

| Pipe Size | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2″ | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | 1500 Class Weight | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4″ | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | 1500 Class Weight | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1″ | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | 1500 Class Weight | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2″ | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | 1500 Class Weight | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2″ | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | 1500 Class Weight | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2″ | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | 1500 Class Weight | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3″ | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4″ | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5″ | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6″ | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8″ | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10″ | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12″ | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14″ | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16″ | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18″ | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20″ | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22″ | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24″ | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

| Size in inches | Outer Dia. | Size in millimeter | RF Height | Flange Thick. | RF Diam. | PCD | Bolt Size UNC | No of Bolts | Machine Bolt Lengths | Hole Size | RF Stud Length | ISO Stud Size | Weight in kg |

| A | D | B | C | E | |||||||||

| 1/2 | 90 | 15 | 2 | 9.6 | 34.9 | 60.3 | 1/2 | 4 | 50 | 5/8 | 55 | M14 | 0.9 |

| 3/4 | 100 | 20 | 2 | 11.2 | 42.9 | 69.9 | 1/2 | 4 | 50 | 5/8 | 65 | M14 | 0.9 |

| 1 | 110 | 25 | 2 | 12.7 | 50.8 | 79.4 | 1/2 | 4 | 55 | 5/8 | 65 | M14 | 0.9 |

| 1 1/4 | 115 | 32 | 2 | 14.3 | 63.5 | 88.9 | 1/2 | 4 | 55 | 5/8 | 70 | M14 | 1.4 |

| 1 1/2 | 125 | 40 | 2 | 15.9 | 73 | 98.4 | 1/2 | 4 | 65 | 5/8 | 70 | M14 | 1.8 |

| 2 | 150 | 50 | 2 | 17.5 | 92.1 | 120.7 | 5/8 | 4 | 70 | 3/4 | 85 | M16 | 2.3 |

| 2 1/2 | 180 | 65 | 2 | 20.7 | 104.8 | 139.7 | 5/8 | 4 | 75 | 3/4 | 90 | M16 | 3.2 |

| 3 | 190 | 80 | 2 | 22.3 | 127 | 152.4 | 5/8 | 4 | 75 | 3/4 | 90 | M16 | 4.1 |

| 3 1/2 | 215 | 90 | 2 | 22.3 | 139.7 | 177.8 | 5/8 | 8 | 75 | 3/4 | 90 | M16 | 5.9 |

| 4 | 230 | 100 | 2 | 22.3 | 157.2 | 190.5 | 5/8 | 8 | 75 | 3/4 | 90 | M16 | 7.7 |

| 5 | 255 | 125 | 2 | 22.3 | 185.7 | 215.9 | 3/4 | 8 | 85 | 7/8 | 95 | M20 | 9.1 |

| 6 | 280 | 150 | 2 | 23.9 | 215.9 | 241.3 | 3/4 | 8 | 85 | 7/8 | 100 | M20 | 11.8 |

| 8 | 345 | 200 | 2 | 27 | 269.9 | 298.5 | 3/4 | 8 | 90 | 7/8 | 110 | M20 | 20.5 |

| 10 | 405 | 250 | 2 | 28.6 | 323.8 | 362 | 7/8 | 12 | 100 | 1 | 115 | M24 | 32 |

| 12 | 485 | 300 | 2 | 30.2 | 381 | 431.8 | 7/8 | 12 | 100 | 1 | 120 | M24 | 50 |

| 14 | 535 | 350 | 2 | 33.4 | 412.8 | 476.3 | 1 | 12 | 115 | 1 1/8 | 135 | M27 | 64 |

| 16 | 595 | 400 | 2 | 35 | 469.9 | 539.8 | 1 | 16 | 115 | 1 1/8 | 135 | M27 | 82 |

| 18 | 635 | 450 | 2 | 38.1 | 533.4 | 577.9 | 1 1/8 | 16 | 125 | 1 1/4 | 145 | M30 | 100 |

| 20 | 700 | 500 | 2 | 41.3 | 584.2 | 635 | 1 1/8 | 20 | 140 | 1 1/4 | 160 | M30 | 130 |

| 24 | 815 | 600 | 2 | 46.1 | 692.2 | 749.3 | 1 1/4 | 20 | 150 | 1 3/8 | 170 | M33 | 196 |

Carbon Steel A105 Flanges find extensive application in many industries because of their strength, versatility, and affordability. They are critical fittings in oil & gas pipelines, petrochemical facilities, power generation systems, and water treatment systems. The flanges ensure leak-free connections in piping systems with secure joints in high-temperature and high-pressure operations. Their strength also finds them applicable in marine engineering, boilers, and heavy-duty mechanical assemblies. A105 flanges are suitable for both threaded and welded fittings, making them versatile for a wide variety of industrial applications where durability and accuracy are needed.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved