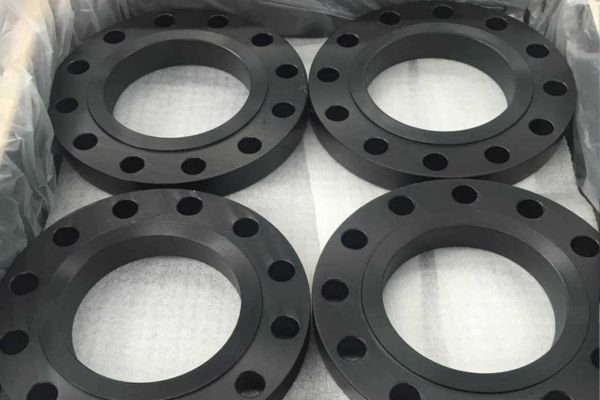

Reputable Carbon Steel A182 Flange manufacturer and supplier Luke Steel, with headquarters in Houston, Houstan, provides premium forged flanges designed for high-temperature and high-pressure applications. These flanges, which meet ASTM A182 standards, are extensively utilised in the chemical processing, petrochemical, oil and gas, and power generation sectors. Luke Steel offers a comprehensive selection of A182 flanges, including blind, socket weld, slip-on, and weld neck styles, all of which are made to withstand harsh service conditions. Luke Steel distinguishes itself as a reliable partner for cutting-edge piping component solutions by emphasising quality, customer service, and prompt delivery.

Carbon Steel A182 Flanges are made from carbon steels or high-strength alloys and usually contain silicon (0.10–0.50%), phosphorus (0.035% max), sulphur (0.040% max), manganese (0.50–1.00%), and carbon (up to 0.30%). With a minimum tensile strength of 70,000 psi and a minimum yield strength of 36,000 psi, they are made to endure high-pressure, high-temperature service. To improve toughness and resistance to fatigue and thermal stress, A182 flanges undergo heat treatment, which includes quenching, tempering, and normalisation. Because of these characteristics, they are perfect for demanding applications that require high temperatures and corrosive or stressful conditions.

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ to 36″

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Luke Steel is one of the most prominent manufacturers and suppliers of superior quality Carbon Steel A182 Flanges in Houstan, USA. As experts in steel solutions, we supply a complete spectrum of products like Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our product range comprises Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets, and Plates. Known for our reliable delivery and first-rate customer service, we are committed to supplying high-quality steel materials that guarantee durability and excellent performance in numerous industrial applications.

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

| Size in inches | Outer Dia. | Size in millimeter | RF Height | Flange Thick. | RF Diam. | PCD | Bolt Size UNC | No of Bolts | Machine Bolt Lengths | Hole Size | RF Stud Length | ISO Stud Size | Weight in kg |

| A | D | B | C | E | |||||||||

| 1/2 | 90 | 15 | 2 | 9.6 | 34.9 | 60.3 | 1/2 | 4 | 50 | 5/8 | 55 | M14 | 0.9 |

| 3/4 | 100 | 20 | 2 | 11.2 | 42.9 | 69.9 | 1/2 | 4 | 50 | 5/8 | 65 | M14 | 0.9 |

| 1 | 110 | 25 | 2 | 12.7 | 50.8 | 79.4 | 1/2 | 4 | 55 | 5/8 | 65 | M14 | 0.9 |

| 1 1/4 | 115 | 32 | 2 | 14.3 | 63.5 | 88.9 | 1/2 | 4 | 55 | 5/8 | 70 | M14 | 1.4 |

| 1 1/2 | 125 | 40 | 2 | 15.9 | 73 | 98.4 | 1/2 | 4 | 65 | 5/8 | 70 | M14 | 1.8 |

| 2 | 150 | 50 | 2 | 17.5 | 92.1 | 120.7 | 5/8 | 4 | 70 | 3/4 | 85 | M16 | 2.3 |

| 2 1/2 | 180 | 65 | 2 | 20.7 | 104.8 | 139.7 | 5/8 | 4 | 75 | 3/4 | 90 | M16 | 3.2 |

| 3 | 190 | 80 | 2 | 22.3 | 127 | 152.4 | 5/8 | 4 | 75 | 3/4 | 90 | M16 | 4.1 |

| 3 1/2 | 215 | 90 | 2 | 22.3 | 139.7 | 177.8 | 5/8 | 8 | 75 | 3/4 | 90 | M16 | 5.9 |

| 4 | 230 | 100 | 2 | 22.3 | 157.2 | 190.5 | 5/8 | 8 | 75 | 3/4 | 90 | M16 | 7.7 |

| 5 | 255 | 125 | 2 | 22.3 | 185.7 | 215.9 | 3/4 | 8 | 85 | 7/8 | 95 | M20 | 9.1 |

| 6 | 280 | 150 | 2 | 23.9 | 215.9 | 241.3 | 3/4 | 8 | 85 | 7/8 | 100 | M20 | 11.8 |

| 8 | 345 | 200 | 2 | 27 | 269.9 | 298.5 | 3/4 | 8 | 90 | 7/8 | 110 | M20 | 20.5 |

| 10 | 405 | 250 | 2 | 28.6 | 323.8 | 362 | 7/8 | 12 | 100 | 1 | 115 | M24 | 32 |

| 12 | 485 | 300 | 2 | 30.2 | 381 | 431.8 | 7/8 | 12 | 100 | 1 | 120 | M24 | 50 |

| 14 | 535 | 350 | 2 | 33.4 | 412.8 | 476.3 | 1 | 12 | 115 | 1 1/8 | 135 | M27 | 64 |

| 16 | 595 | 400 | 2 | 35 | 469.9 | 539.8 | 1 | 16 | 115 | 1 1/8 | 135 | M27 | 82 |

| 18 | 635 | 450 | 2 | 38.1 | 533.4 | 577.9 | 1 1/8 | 16 | 125 | 1 1/4 | 145 | M30 | 100 |

| 20 | 700 | 500 | 2 | 41.3 | 584.2 | 635 | 1 1/8 | 20 | 140 | 1 1/4 | 160 | M30 | 130 |

| 24 | 815 | 600 | 2 | 46.1 | 692.2 | 749.3 | 1 1/4 | 20 | 150 | 1 3/8 | 170 | M33 | 196 |

Refineries, chemical processing, power generation, and the oil and gas sector all make extensive use of carbon steel A182 flanges. They are made to operate in boilers, reactors, heat exchangers, and pipelines at high temperatures and pressures. These flanges are frequently used to join valves, pumps, and piping in steam, gas, and fluid systems because they offer safe, leak-proof connections under challenging operating conditions. Both onshore and offshore applications, such as high-temperature lines in petrochemical plants and fossil fuel power stations, can benefit from their mechanical strength and resistance to corrosion. Additionally, A182 flanges facilitate simple system upgrades and maintenance in vital systems.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved