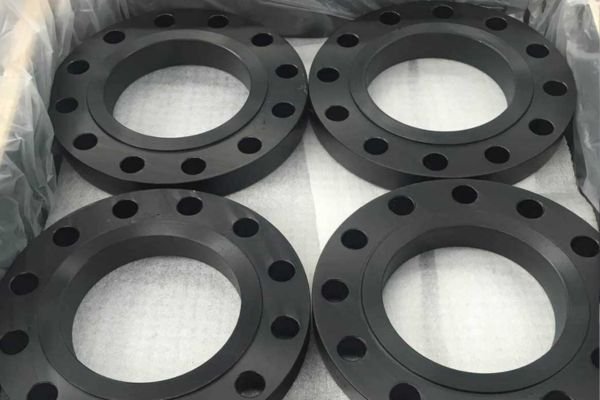

Luke Steel is a highly reputed producer and supplier of Carbon Steel A694 Flanges in Houston, USA. These flanges are specifically made for transmission systems under high pressure and are suited for use in oil and gas pipelines, power plants, and petrochemical plants. They are produced according to ASTM A694 standards. Luke Steel supplies different kinds such as weld neck, slip-on, blind, socket weld, and threaded flanges. Established for providing strength, ruggedness, and pressure-resistance, the company provides quality testing and on-time delivery. Luke Steel supplies domestic and international markets with carbon steel flanges that match performance as well as safety standards in harsh conditions.

Carbon Steel A694 Flanges are produced with up to 0.30% carbon and manganese, phosphorus, sulfur, silicon, and trace elements. Flanges are usually normalized or quenched and tempered to provide strength. They have high tensile strength (≥485 MPa), yield strength (≥250 MPa), and elongation of ≥20%, grade-dependent (such as F42, F52, F60, F65, F70). The product offers superior impact toughness, weldability, and pressure stress resistance, making it an ideal candidate for severe pipeline and structural use.

| Specifications | ASTM A694 / ASME SA694 |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI, ASME, BS, DIN, EN etc. |

| Grades | F42, F46, F52, F60, F65, F70, A36, A516 Gr. 70,60 |

| Size | 1/2″ to 48″ |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Element | F42 Content, % | F52 Content, % | F60 Content, % | F65 Content, % | F70 Content, % |

| Carbon (C) | 0.13~0.20 | 0.16~0.22 | 0.17~0.23 | 0.17~0.23 | 0.06~0.10 |

| Silicon (Si) | 0.20~0.40 | 0.15~0.40 | 0.15~0.40 | 0.15~0.40 | 0.20~0.40 |

| Manganese (Mn) | 1.20~1.60 | 1.10~1.40 | 1.20~1.50 | 1.30~1.60 | 1.10~1.40 |

| Phosphorous (P) | ≤ 0.030 | ≤ 0.025 | ≤ 0.020 | ≤ 0.025 | ≤ 0.020 |

| Sulfur (S) | ≤ 0.020 | ≤ 0.012 | ≤ 0.012 | ≤ 0.015 | ≤ 0.010 |

| Molybdenum (Mo) | 0.20~0.35 | 0.45~0.60 | 0.45~0.65 | 1.20~1.70 | |

| Nickel (Ni) | ≤ 0.30 | ≤ 0.50 | 0.40~1.00 | ≤ 0.30 | 0.20~0.40 |

| Chromium (Cr) | ≤ 0.30 | ≤ 0.30 | ≤ 0.25 | ≤ 0.30 | ≤ 0.30 |

| Copper (Cu) | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 |

| Vanadium (V) | ≤ 0.050 | 0.02~0.06 | |||

| Niobium (Nb) | 0.025~0.050 | ||||

| Pcm | ≤ 0.25 | ||||

| Carbon Equivalent | ≤ 0.48 | ≤ 0.48 | ≤ 0.48 | ≤ 0.43 | ≤ 0.48 |

| ASTM A694 Grade | Yield Strength min. | Tensile Strength min. | Elongation min. | ||

| MPa | ksi | MPa | ksi | % | |

| A694 F42 FLANGES | 290 | 42 | 415 | 65 | 20 |

| A694 F46 FLANGES | 315 | 46 | 415 | 60 | 20 |

| A694 F48 FLANGES | 330 | 48 | 425 | 62 | 20 |

| A694 F50 FLANGES | 345 | 50 | 440 | 64 | 20 |

| A694 F52 FLANGES | 360 | 52 | 455 | 66 | 20 |

| A694 F56 FLANGES | 385 | 56 | 470 | 68 | 20 |

| A694 F60 FLANGES | 415 | 60 | 515 | 75 | 20 |

| A694 F65 FLANGES | 450 | 65 | 530 | 77 | 20 |

| A694 F70 FLANGES | 485 | 70 | 565 | 82 | 18 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Luke Steel is one of the most prominent manufacturers and suppliers of superior quality Carbon Steel A694 Flanges in Houstan, USA. As experts in steel solutions, we supply a complete spectrum of products like Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our product range comprises Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets, and Plates. Known for our reliable delivery and first-rate customer service, we are committed to supplying high-quality steel materials that guarantee durability and excellent performance in numerous industrial applications.

| ASME/ANSI B 16.5 | Welding Neck, Slip on, Blind, High Hub Blind, Socket Weld, Lap Joint, Threaded, Ring Type Joint Flanges |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck, Blind [Series A & B] Flanges |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck, Slip on, Threaded Flanges |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck, Hubbed Slip on, Hubbed Threaded, Lapped Pipe End, Plate, Loose Plate, Loose Plate With Weld Neck, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck, Hubbed Slip-On Hubbed Threaded, Plate, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck, Socket Welding, Slip-On, Blind, Screwed Boss, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck, Plate Slip-On, Screwed Boss, Slip-On Boss, Blind Flange |

| TABLE | D, E, F, H |

| DIN Flange | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |

A694 Flanges made of Carbon Steel are extensively utilized in oil & gas transmission pipelines, refinery piping systems, power generation equipment, and chemical processing facilities. Constructed for high-pressure usage, they provide tight, leakage-free connections in pumps, valves, pipes, and other equipment. Natural gas and oil exploration uses them prominently, particularly in environments needing aggressive mechanical properties under changing pressure and temperature. Their strength and stress resistance make them well-suited for offshore platforms, pipeline welding ends, and compressor stations. They may also be utilized in hydraulic and steam systems, providing long-lasting reliability and performance under harsh conditions.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved