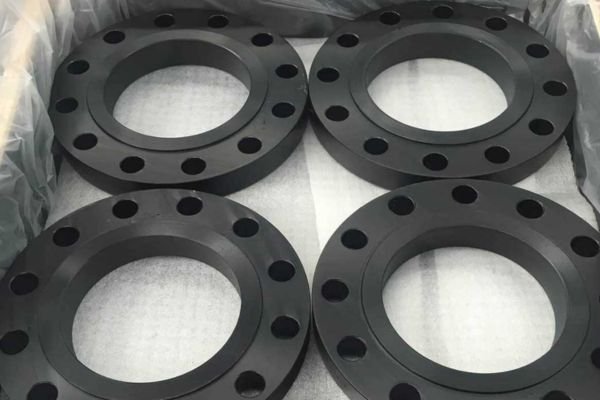

Luke Steel is a reputable manufacturer and supplier located in Houston, Houstan, focusing on high-quality piping components like Low Temperature Carbon Steel LF787 Flanges. Known for their precision-engineered, high-performance flanges, Luke Steel caters to industries that need safe and reliable connections in sub-zero and cryogenic environments. Their LF787 Flanges are crafted to comply with stringent international standards for low-temperature applications, ensuring outstanding durability and performance. With state-of-the-art production facilities and a talented team, Luke Steel promises timely delivery and consistent quality to meet the demands of projects in the oil, gas, petrochemical, and power generation sectors.

Low Temperature Carbon Steel LF787 Flanges are constructed from carbon steel with carefully controlled levels of carbon, manganese, phosphorus, sulfur, and silicon, along with alloying elements like nickel to enhance low-temperature toughness. These flanges offer excellent impact resistance at temperatures as low as -50°F (-45°C) while maintaining strong tensile and yield strength. Their fine-grain microstructure ensures high ductility and reliable weldability. Designed to prevent brittle fractures in cold conditions, LF787 Flanges provide tight, leak-proof connections and uphold structural integrity even in extreme operating environments.

| Element | Composition |

|---|---|

| Carbon, max | 0.07 |

| Manganese | 0.40–0.70 |

| Phosphorus, max | 0.025 |

| Sulfur, max | 0.025 |

| Silicon [Note A] | 0.40 max |

| Nickel | 0.70–1.00 |

| Chromium | 0.60–0.90 |

| Molybdenum | 0.15–0.25 |

| Copper | 1.00–1.30 |

| Columbium | 0.02 min |

| Vanadium | 0.03 max |

| Tensile Class | Tensile Strength, ksi [MPa] | Yield Strength, min, ksi [MPa] [Note B, C] | Elongation | Reduction of Area, min, % | |

|---|---|---|---|---|---|

| Round Specimen in 4D, min, % | Strip Specimen in 2 Inch [50mm], min, % | ||||

| Class 2 | 65–85 [450–585] | 55 [380] | 20 | 28 | 45 |

| Class 3 | 75–95 [515–655] | 65 [450] | 20 | 28 | 45 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Luke Steel is one of the most prominent manufacturers and suppliers of superior quality Low Temperature Carbon Steel LF787 Flanges in Houstan, USA. As experts in steel solutions, we supply a complete spectrum of products like Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our product range comprises Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets, and Plates. Known for our reliable delivery and first-rate customer service, we are committed to supplying high-quality steel materials that guarantee durability and excellent performance in numerous industrial applications.

| ASME/ANSI B 16.5 | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, LTCS A350 LF787 Lap Joint Flange, Threaded Flange, LTCS A350 LF787 Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Slip on Flange, LTCS A350 LF787 Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Hubbed Slip on Flange, LTCS A350 LF787 Hubbed Threaded Flange, Lapped Pipe End Flange, LTCS A350 LF787 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Hubbed Slip-On Hubbed Threaded, Plate Flange, LTCS A350 LF787 Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | LTCS A350 LF787 Welding Neck Flange, Socket Welding Flange, LTCS A350 LF787 Slip-On Flange, LTCS A350 LF787 Blind Flange, LTCS A350 LF787 Screwed Boss Flange, LTCS A350 LF787 Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | LTCS A350 LF787 Welding Neck Flange, LTCS A350 LF787 Plate Slip-On Flange, LTCS A350 LF787 Screwed Boss Flange, Slip-On Boss Flange, LTCS A350 LF787 Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.lf2 | 18.00 | 1/2 | 1-15/16 |

| lf2 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | lf2.lf2 | lf2.25 | lf2.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | lf2 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 2lf2 | 165 |

| lf2 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 2lf2 | 2lf2 | 2lf2 | 275 | 430 | 268 |

LF787 Flanges are extensively used in industries such as oil and gas, LNG, petrochemical plants, refineries, and power generation facilities, where piping systems must function reliably in low-temperature or cryogenic conditions. Typical applications include connecting pipelines, pressure vessels, heat exchangers, storage tanks, and other essential equipment that transport or process low-temperature fluids or gases. Their impressive impact strength, ductility, and weldability minimize the risk of leaks and brittle failures. LF787 Flanges ensure safe and efficient flow control and structural performance, making them essential for demanding cold-service operations.

Luke Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Houstan, USA.

Copyright 2025 Luke Steel. All rights reserved